The Material That Defines a Premium Artificial Christmas Tree

100% PE Needles vs. Traditional PE-PVC mix

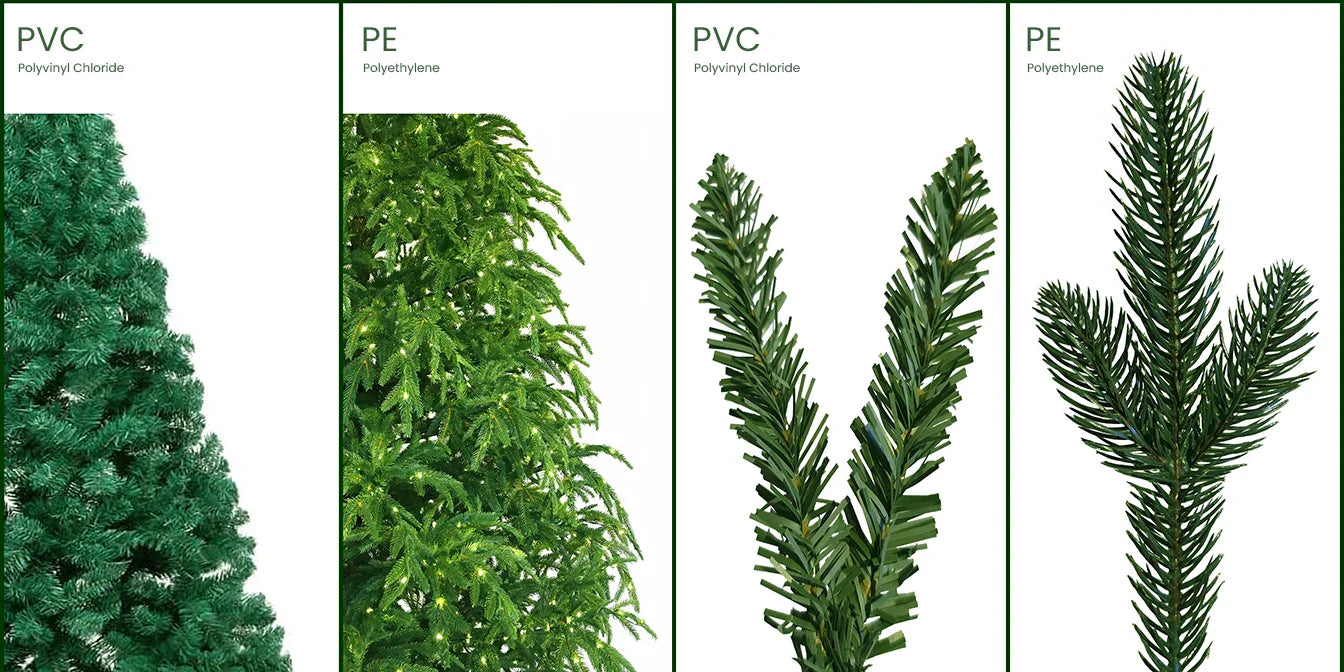

When shopping for a premium artificial Christmas tree, the first detail to examine is the needle material. The difference between polyethylene (PE) and polyvinyl chloride (PVC) needles is striking both visually and tactilely.

100% PE needles are individually moulded to replicate real pine needles with remarkable accuracy. Unlike flat PVC needles, PE branches feature three-dimensional texture, varied thicknesses, and subtle colour variations that catch light just like a freshly cut tree. Running your hand along PE branches feels substantially more realistic than the sometimes prickly or paper-like sensation of PVC needles. However, most trees marketed as “premium” still rely heavily on PVC tips inside the structure, reserving PE tips for the outer shell only.

High-end artificial trees typically feature either 100% PE construction or a significantly higher PE-to-PVC ratio. Budget models, by contrast, rely heavily on PVC needles which, while affordable, lack the dimensional realism that defines a luxury tree.

Perhaps most importantly, PE needles maintain their shape, colour, and overall appearance for multiple holiday seasons. Unlike PVC branches that may flatten, fade, or develop an artificial sheen over time, quality PE branches continue looking fresh year after year.

Moulded-Needle Technology: The Gold Standard in Realism

The most realistic artificial trees use a form of 3D moulded-needle technology, where multi-toned, injection-moulded PE is shaped using casts taken from real evergreen branches. This method produces botanically accurate tips with natural colour variation and true branch geometry.

The most realistic artificial trees use a form of 3D moulded-needle technology, where multi-toned, injection-moulded PE is shaped using casts taken from real evergreen branches. This method produces botanically accurate tips with natural colour variation and true branch geometry.

- This moulded-needle method incorporates varied needle lengths and multi-tone colour gradients to replicate the natural growth patterns of real tree species. The needles are not a single flat colour—high-quality moulds reproduce the subtle variegations found in nature, from deeper inner greens to slightly lighter, sun-kissed tips.

The highest quality models take this attention to detail further, featuring individually molded branch structures rather than mass-produced, identical branches. This creates the authentic asymmetry and natural variation found in forest-grown trees.

PVC Needles: How They Differ from PE Needels

PVC needles are created for one reason: to keep manufacturing costs down. Their construction reflects that:

- Sliced from inexpensive flat plastic sheet

- Twisted onto wire in uniform strips

- Spray-painted to imitate colour depth for some models

This process is fast, cheap, and mass-producible—perfect for budget trees, but it comes at the expense of realism. PVC needles are flat, shiny, and repetitive, lacking the natural taper, texture, and multi-tone depth that define a premium tree.

Because PVC is so inexpensive, many lower-priced trees depend on it for the majority of their fullness. It’s the material used to fill gaps and boost tip count without increasing realism.

Even, most premium-priced sellers also use low-cost PVC to inflate fullness. The pattern is consistent: cheap PVC strips packed deep inside the tree for bulk, then a thin outer shell of PE tips added to create surface realism. From a distance it looks convincing, but the inner PVC remains visible through gaps once the branches are shaped.

These inner PVC strands behave like the material they are. The cut PVC slivers shed, fall to the floor, and reappear every time the tree is fluffed or reset. The result is predictable: surface realism with a core built from budget components.

Over time, PVC needles often:

- lose shape

- flatten under storage pressure

- fade or develop a plasticky sheen

In contrast, moulded PE holds its structure and colour for many seasons, which is why PE—not PVC—is the benchmark material for high-quality, ultra-realistic artificial Christmas trees.

Branch Density, Tip Count, and Fullness Metrics

A truly high quality artificial tree boasts significantly higher tip counts than standard models. While budget trees might feature 1,000 tips for a 7.5' tree, premium options include 1,500-3,000+ branch tips for the same height, creating a substantially fuller appearance.

Higher-end trees use multi-layered branch construction, where inner branches create depth and outer branches deliver fine detail. This layered approach produces dimensional fullness and prevents the “see-through” gaps often seen in lower-cost artificial trees.

Luxury models frequently incorporate hinged branches with memory wire, which simplifies setup while ensuring branches return to their intended position year after year. This engineering detail preserves the tree's carefully designed profile through multiple seasons of use.

Realistic Colour Variations and Subtle Detailing

The visual realism of a premium artificial Christmas tree extends beyond the needles themselves. Top-tier models feature multiple green tones, naturally brown inner stems, and sometimes subtle frosting or variegation on select tips.

For the most discriminating buyers, these subtle details combine to create an artificial tree that's virtually indistinguishable from its forest-grown counterpart—even before adding a single ornament.

Why Full-PE Trees Are Limited in the Market and Not Widely Offered

While Twinkle n Grace offers full-PE (100% PE) Christmas trees, they remain hard to find elsewhere. Full-PE construction sits at the very top of artificial tree craftsmanship, requiring high-precision moulds, larger amounts of premium PE material, and slower, carefully controlled production cycles. These factors make full-PE trees expensive to produce, which is why most retailers—even well-established ones—rarely offer them.

Instead, the common industry shortcut looks like this:

• a thin outer shell of moulded PE (typically 20–65%)

• a PVC core that provides most of the tree’s bulk and density

• marketing terms such as “mixed tips,” “PE blend,” or “realistic PE” to suggest a premium finish

From a distance, these trees can appear convincing. But once you start shaping the branches, the inner construction becomes clear: the depth, structure, and fullness are mostly created from inexpensive PVC. The realism is only skin-deep.

This layered approach produces a stylised, imitation look rather than a truly lifelike evergreen. Needle definition is flatter, shadowing is shallower, and the natural organic forms created by full-PE moulds simply aren’t present.

Because the R&D and production cost difference is significant, genuine full-PE trees are produced by only a very small number of brands in the Australian and global market—primarily Twinkle n Grace in Australia, which absorbs the higher production expense without imposing a significant price increase compared with blended PE-PVC suppliers, delivering authentic, top-tier realism without additional cost to the consumer.

Final Summary

A premium artificial Christmas tree is defined by material quality. 100% PE needles set the highest standard for realism, delivering natural texture, colour variation, and multi-season durability. PVC needles, flat and mass-produced, exist to reduce cost and create bulk, not realism.

Many so-called premium trees hide large amounts of PVC inside the structure, using PE only at the surface. This limits realism and reduces long-term performance.

Producing a full-PE tree demands precision mould tooling, high material volumes, and slow production cycles. For this reason, full-PE trees are not commonly offered in the global market, with only a very limited number of premium and luxury brands choosing to manufacture them.

In Australia, Twinkle n Grace stands out as the only brand offering a complete tree range constructed entirely from 100% moulded PE needles, with no PVC filler at all.